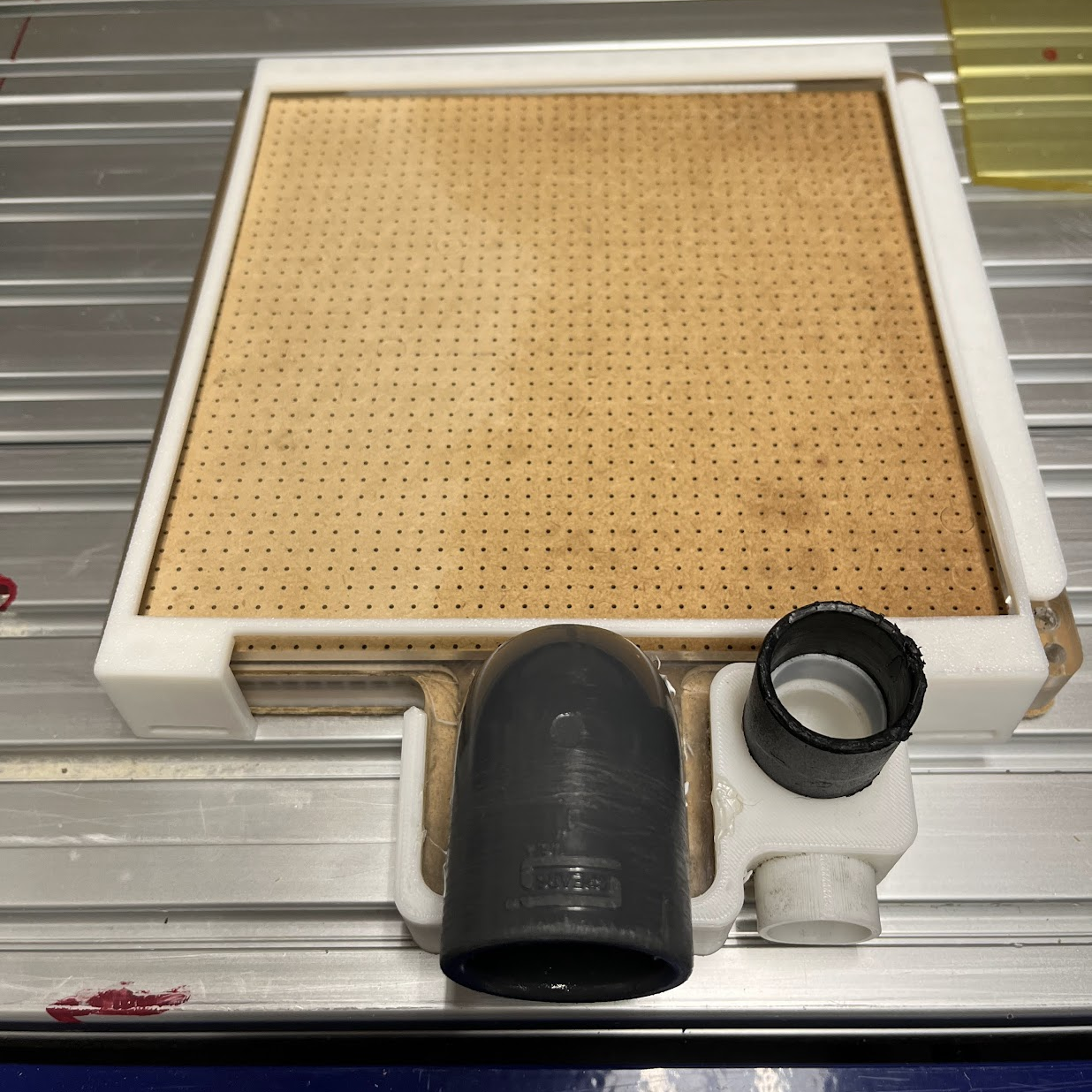

During my work as a postdoctoral research fellow at Haverford College myself and an undergraduate research student have set out to find a way to gently cut cylinders from sheets of polyurethane in a way that preserves the material’s optical properties. This process is not trivial, other research groups have attempted to make a similar process work with mixed success. None the less, after a summer of diligent effort the student researcher handed off a working process that simply needed refinement. I designed an all-in-one version of the initial process which incorporated a vacuum table with a clamping bracket work holding solution and shop-vac assisted cylinder collection apparatus. This set-up bolts directly onto the existing hardware of the mill and includes a high accuracy zeroing solution to protect the cutting tool. Ongoing work on this problem includes working with a skilled lathe expert to create custom tools out of hardened steel with key design adjustments to a commercial tool that didn’t quite fit our needs.