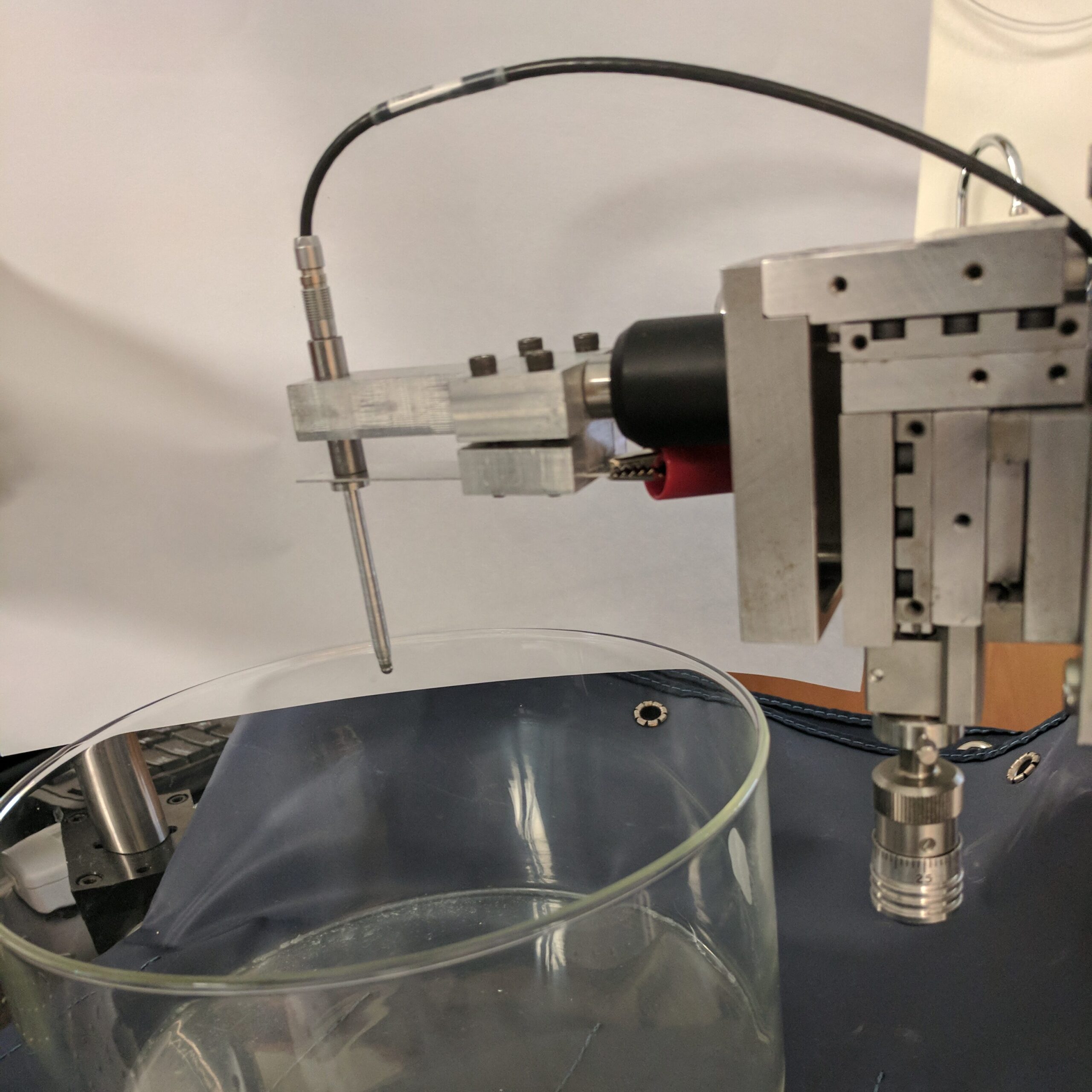

My first project as a graduate student in Joey Paulsen’s lab at SU was centered around the force of indentation of ultra-thin polymer films floating on a water bath. We wanted to measure this force over a large range of indentation and found the commercially available force sensors unhelpful in the range of forces we needed to resolve. Thankfully a colleague of Joey’s from UMass Amherst was able to share the designs of an apparatus they used to do the only other study of this particular system. I contacted the engineering department to get trained up on safely using machine shop mills and lathes so I could make my own. Using aluminum I made the transduction appartatus, on the far left as well as the shim and indentation probe on the bottom left of the middle image below. I used thermoplastic to make the hooked probe on the upper left of the middle image which allowed us to study the mirror case where the film is indented from below. I used a capacitive sensor, a modified trigger button assembly, and data acquisition card to synchronize the triggering of video, force data, and positional data. This apparatus was featured in Timounay et al. PRX 2020 and Ripp et al. Soft Matter 2021 as well as my dissertation: Buckling Patterns and Mechanics of Thin Interfacial Polymer Films 2021 available via SURFACE at SU.